Manufacturing ovens and furnaces according to industry standards

We carry out constant monitoring of technology and standards in order to improve your equipment, allowing us to master all developments in the environments specific to your sector of activity.

AMS2750, AMS2770, NADCAP, BAC5621, RPS953,

CQI-9,

ATEX (Explosive Atmospheres), UL, GOST, etc.

For the aviation industry, the AMS 2750 standards and their AMS 2770 derivatives (Aerospace Material Specifications) are applicable to industrial treatment of top-quality materials and heat treatment of aluminium alloys.

For the automotive industry, the CQI-9 standard also aims to subject heat treatment processes to stricter rules.

Heat treatment installations must guarantee the following:

- Temperature uniformity in the working space (TUS)

- Instrumentation (definition of the measuring and control equipment)

- Calibration of the measurement path (IT) between the controller and the thermocouple, including the measurement line

- System accuracy tests (SAT)

Documentation of test cycles:

Compliance with provisions and standards is essential to guarantee the level of quality which the components must meet, even if they are mass-produced. That is why it is necessary to carry out extensive and repeated tests, including testing of the instruments, and to draw up documentation.

Under the requirements of the AMS 2750 standard, the customer must also specify

- The furnace class (temperature uniformity class)

- The type of instrumentation (control instruments, means of recording and thermocouples used).

The more demanding the furnace class, the more accurate the instruments must be.

| Furnace

class |

Temperature

uniformity TUS – Temperature Uniformity Surveys |

Maximum difference

in SAT – System Accuracy Test |

|

| °C | °C | % of reading | |

| 1 | ± 3 | ± 1,1 | 0,2 |

| 2 | ± 6 | ± 1,7 | 0,3 |

| 3 | ± 8 | ± 2,2 | 0,4 |

| 4 | ± 10 | ± 2,2 | 0,4 |

| Type of instrumentation | |||||||

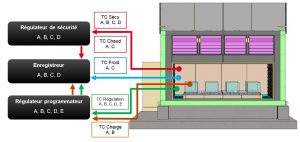

| Required for each zone | TC name | TC connected to | A | B | C | D | E |

| At least 1 sensor connected to 1 controller | Control TC | Régulateur programmateur | X | X | X | X | X |

| Recording of control sensor | Control TC | Recorder | X | X | X | X | |

| Recording of control sensor | Hot TC | Recorder | X | X | |||

| Recording of Cold point | Cold TC | Recorder | X | X | |||

| Recording of load sensor | Load TC | Recorder | X | X | |||

| Overheating protection | Safety TC

or Hot TC |

Safety controller | X | X | X | X | |

Regular tests:

The standard defines the intervals for testing of the instruments

System Accuracy Test (SAT) and furnace temperature uniformity test (TUS = Temperature Uniformity Survey).

The SAT/TUS tests must be carried out by the customer with measuring devices and sensors which operate independently from the furnace’s instruments.