Manufacturer of heat treatment furnaces for the aerospace industry

SAT designs and manufactures industrial heating equipment which is essential in the manufacturing processes of civil or military aircraft and spacecraft components and in aluminium alloy heat treatment and composite material transformation processes.

Heat treatment FURNACES for aircraft sheet metal work

Furnaces adapted to heat treatment of the various metallurgical states of aluminium alloys: T4, T5, T6, T7 and T8.

Wing leading edges, air intake lips, exhausts, tail panels, wing panels, fuselage parts, rivets, etc.

These are all parts and components which must undergo pre-heating, solution treatment + quenching and tempering processes for which SAT industrial heating installations are recognized worldwide.

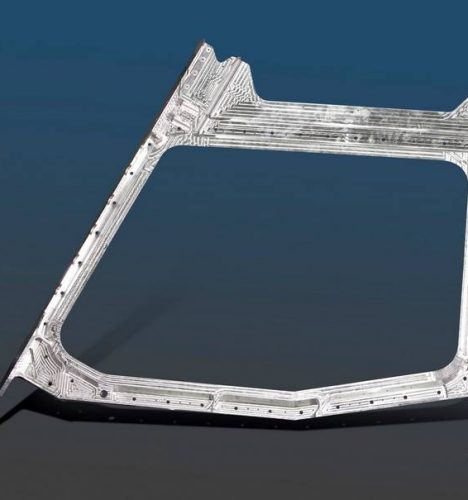

HEAT TREATMENT FURNACES FOR MANUFACTURING OF STRUCTURAL PARTS

Frames, spars, ribs, fittings, seat rails, winglets, etc. are all parts which require heat treatment after machining.

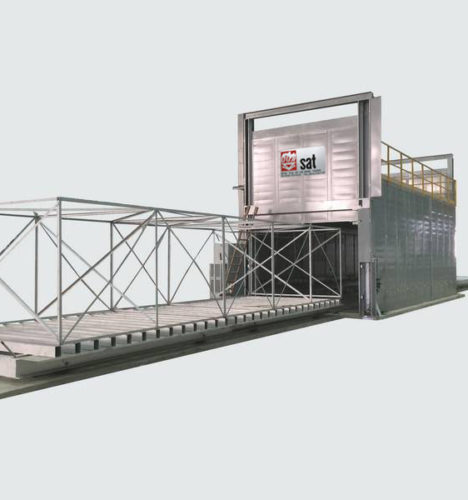

Heat treatment FURNACES & TUNNELS for forging

The key to success for forged parts is the quality of the heat treatment.

SAT has gained worldwide recognition thanks to its unique know-how in design of high-performance heating equipment lines.

SAT masters the various forging heat treatment processes: pre-heating, solution treatment + quenching and tempering on heavy parts (12 tonnes) or large parts (fuselage ring of diameter 10 m) in compliance with the most restrictive aviation standards: AMS2750, BAC, RPS, etc. Nacelles, shaped splice plates, cross members, rings, girders, spars, etc. are all parts which require T4, T5, T6, T7 and T8 type heat treatment in high-technology equipment.

SAT is the only company to have developed and mastered “Conveyor furnace” technology for heavy parts (over 20 tonnes).

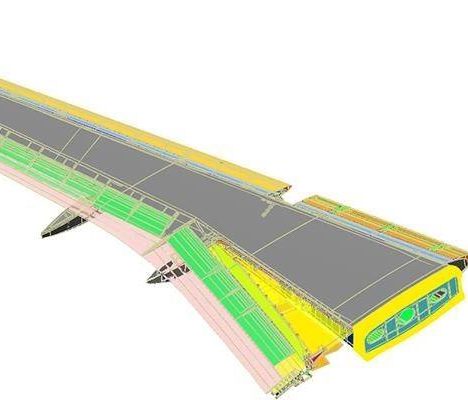

Composite part CURING OVENS

Turnkey production lines for manufacturing of composite parts by infusion or RTM.

Large ovens (length: 22 meters) for infusion of carbon aircraft wings.

- Curing ovens up to 450 °C for any type of resin

- Structural parts

- Fuselage

- Inspection hatches, carbon wings

- Interior furnishings